In offshore operations, managing waste is far more complex than simply collecting and disposing of it. Space is limited, logistics are tightly coordinated, and the environmental regulations are strict. This makes specialized waste solutions not just helpful, but absolutely essential. The role of the Offshore Container in this process is often underestimated, especially when it comes to handling different waste streams effectively and safely. Offshore waste containers are purpose-built to meet these challenges, offering operators an efficient, compliant, and secure method to manage both hazardous and non-hazardous waste on rigs, platforms, and vessels.

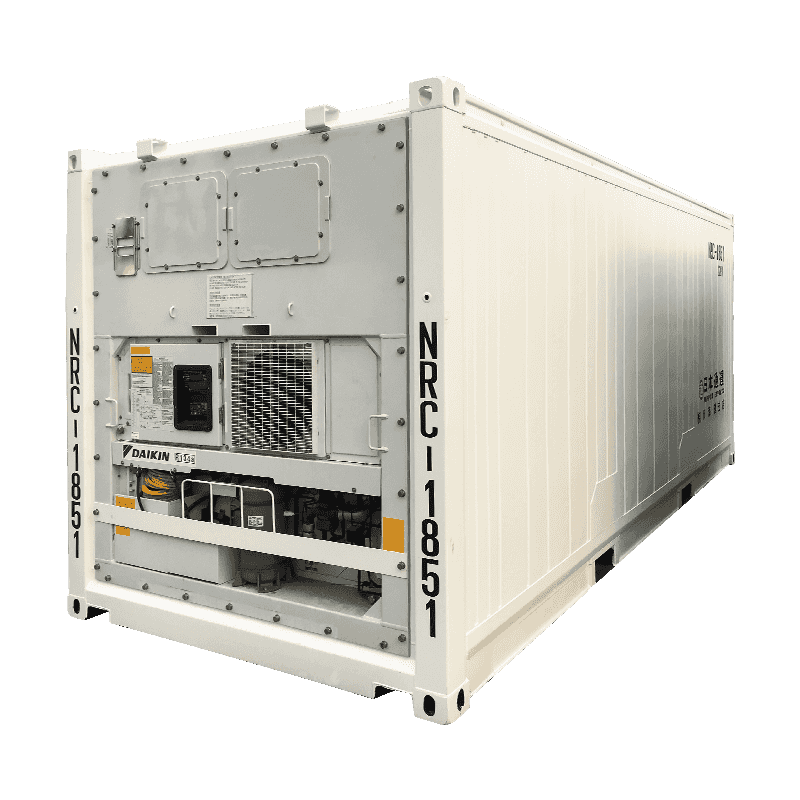

Each type of offshore waste container is engineered with a specific function in mind, from sealed bins for oily rags and chemical waste to open-top units for scrap metal or general debris. These containers are designed to comply with international standards, including DNV 2.7-1, which ensures they can withstand offshore transport conditions and environmental stressors. More importantly, their structural integrity and leak-proof construction help prevent contamination risks—a crucial factor when dealing with materials that could threaten both personnel safety and the marine ecosystem. In this context, using a generic or poorly made waste unit simply isn't an option.

Effective waste segregation is another critical aspect of offshore operations, and the right container setup plays a key role. Offshore waste containers often include internal partitioning, clear labeling, and color-coding systems to make sorting waste easier, even in high-pressure work environments. By making proper disposal intuitive, these design features reduce the risk of human error and support compliance with onboard waste management plans. This not only helps avoid costly fines from regulatory authorities but also aligns with the growing expectations for sustainability and environmental stewardship in the energy sector.

Handling and transport are equally important in the offshore setting, where container movement involves cranes, lifts, and transfers across challenging terrain. Offshore container units used for waste must have reinforced lifting points, durable stacking frames, and easy access for both manual and mechanical loading. Safety is a top priority—not just for the crew but for the long-term viability of operations. Properly designed waste containers ensure that even during rough weather or emergency conditions, waste materials stay contained, secured, and traceable.

Another dimension of waste management offshore is the documentation and traceability of disposal processes. Modern offshore waste containers often come with RFID tags or integrated inventory systems that help operators monitor fill levels, container usage, and transportation data. These technologies support better decision-making and allow for more transparent reporting to environmental authorities. For operators looking to streamline offshore logistics, this level of detail can translate into smoother audits, stronger ESG reporting, and greater operational control.

At Yichengke, we understand that waste is more than just a byproduct—it’s a responsibility. Our range of Offshore Container products includes waste units designed specifically for offshore use, balancing safety, functionality, and compliance. Whether you’re managing hazardous fluids, dry debris, or multi-stream waste, our containers help make the process safer, smarter, and more efficient. With decades of experience in offshore equipment manufacturing, we provide not just containers, but confidence in your compliance and operational integrity.

English

English русский

русский Español

Español عربى

عربى