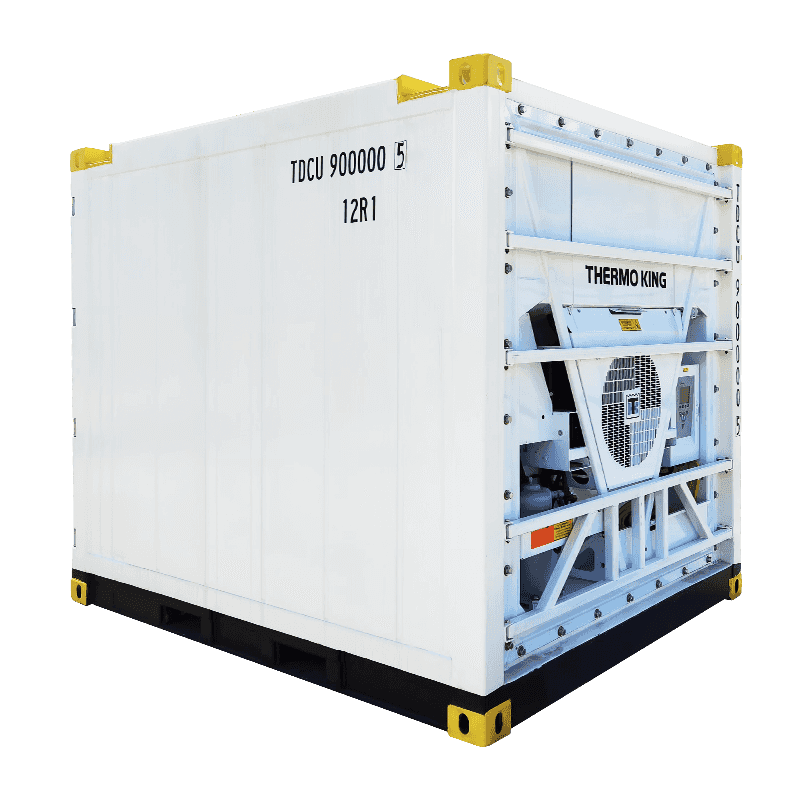

When it comes to offshore operations, the quality of equipment used can directly impact safety, efficiency, and long-term costs. Among the most critical elements is the Offshore Container—a specialized unit designed to withstand the unpredictable nature of marine environments. Unlike standard containers, these are built to endure extreme conditions like high humidity, salt-laden air, violent sea motion, and temperature fluctuations. The materials used in their construction aren’t just important—they’re vital to ensuring both performance and compliance with international standards like DNV 2.7-1.

High-quality offshore containers are typically manufactured using corrosion-resistant steel, often Corten or marine-grade stainless steel, which naturally forms a protective layer that resists further oxidation. This material choice is far from arbitrary. In harsh offshore climates, standard steel can degrade quickly, leading to compromised structural integrity and increased safety risks. By choosing containers made with premium materials and advanced coating systems such as multi-layer marine paint or hot-dip galvanization, operators gain a measurable edge in durability and compliance. These aren’t just boxes—they’re engineered for survival in the most demanding work environments.

The welding and assembly techniques also play a major role in defining a container’s resilience. Certified offshore containers must meet stringent weld quality and inspection standards to ensure they can safely handle dynamic lifting, heavy loads, and rough handling at sea. Key structural points—like corner castings, pad eyes, and base frames—require precision engineering to withstand shock loads during lifting or wave impact. The choice of joining techniques and reinforcements can significantly affect fatigue life, especially for containers used in daily offshore logistics.

Insulation, sealing, and internal fit-outs also matter more than many people assume. Offshore containers, especially those serving as equipment cabins or storage for sensitive materials, need protection not just from structural corrosion but also from condensation and temperature swings. A well-insulated container helps safeguard internal systems and can extend the operational life of valuable assets housed within. Proper sealing with marine-grade gaskets and weatherproof hardware ensures that the contents remain protected even under stormy or high-spray conditions. These are small design choices that add up to significant long-term reliability.

Another key consideration is the lifecycle performance of offshore containers. Low-cost, poorly protected units might save money upfront but often incur higher maintenance and replacement costs over time. Investing in a container with superior build quality reduces downtime, minimizes repair interventions, and helps avoid non-compliance penalties. From a long-term operational perspective, a quality-built offshore container doesn’t just store equipment—it protects productivity. For buyers looking to lower total cost of ownership, choosing a container from an experienced, standards-compliant manufacturer is not only wise but essential.

At Yichengke, we understand the stakes and the standards. Our offshore container solutions are designed with deep industry knowledge, built to meet strict international codes, and tailored for real-world offshore use. Whether you need rugged dry containers, custom equipment cabins, or specialty waste units, our manufacturing precision ensures lasting performance. Because in offshore environments, every detail counts—and quality is the one investment that always delivers.

English

English русский

русский Español

Español عربى

عربى